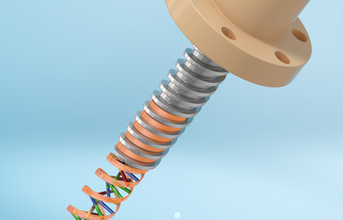

The evolution of the trapezoidal thread: low wear and noise, but instead a long service life and high efficiency. That is what igus promises with its dryspin technology (Source: igus GmbH)

Trapezoidal threads have been mechanical engineering classics for decades. Motion plastics specialists rely on optimised interaction between the metal lead screw and the plastic lead screw nut geometries.

30 per cent longer service life, 82 per cent efficiency

At igus, the nut's thread flanks are larger than those of classic trapezoidal threads, as is the width of the lead screw. This is a small change, but it has significant consequences: enlarging the thread flank results in more high-performance plastic used for power transmission. This means more tribologically optimised material, i.e., regarding friction and wear. "The asymmetry has enabled us to extend the service life so that it is about 30 per cent longer than that of symmetrical trapezoidal threads," said Thorben Hendricks, Head of the dry spin Lead Screw Drive Business Unit at igus. "Optimising the flank angle also increases the amount of energy supplied that can be used. We have flattened the flank angles of the lead screw nut and lead screw. This gives us above-average efficiency - up to 82 per cent at high pitches," he added.

Lead screws work almost noiselessly and with low vibration

The new dryspin thread technology is durable, efficient and quieter than many conventional trapezoidal threads. This is because the tooth flanks are not angular but rounded, reducing the contact area between the lead screw nut and lead screw. This leads to less vibration, which can take the form of rattling or squeaking. Hendricks remarked, "The rounded tooth flanks allow the lead screws to move almost silently without vibration. The lead screw manufacturing tolerance is tighter than specified in DIN 103 7e, ensuring more precise operating behaviour, allowing for much higher speed in the application."

New installations in dryspin lead screw technology portfolio

igus began establishing its lead screw technology on the market in 2013, initially as an alternative to high helix threads. Now there are eight new installation sizes - harmonised lead screws and lead screw nuts, including dimensions with low pitches that enable quick one-to-one replacement of installed trapezoidal threads. The new lead screws are available with pitches of 6.35x6.35 RH, 8x40 RH, 10x3 LH, 12x25 LH, 14x4 RH, 16x5 RH, 18x4 RH and 20x10 RH. The lead screws are made of stainless steel or aluminium; the lead screw nut material can be selected from seven high-performance plastics and several geometries - from a cylindrical design with flange or spanner flats to a version with spring pre-load.