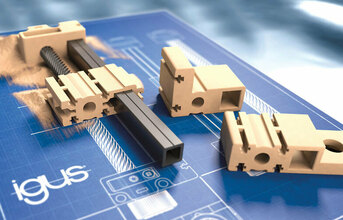

Self-lubricated and low wear

The 3D print is ideally suited to realise individual wishes down to the smallest detail. The customer not only receives his custom-made lead screw unit in a very short time, but can also implement own ideas for profiles, stroke lengths or fastening options. The iglidur I3 material is used in the drylin SLTI3 lead screw unit, the SLS material from igus for selective laser sintering, with which the most complex shapes can be precisely manufactured. The process also endows the components with high strength, which require no more support structures with subsequent reworking. Extensive tests conducted on the large 2,750-square-metre floor area of the igus test laboratory with counterparts made from different materials have shown that iglidur I3 is at least three times more abrasion resistant compared to conventional SLS materials, both in the pivoting, rotating and linear motion. The igus 3D printing service enables an efficient production of single pieces or small batches.

END