What this means for the manufacturer is an unprecedented opportunity to make informed decisions that will help to improve productivity, reduce wastage, increase efficiency and, ultimately, drive up overall profitability.

Of course, the key to the success of any big data analysis is going to be the quality of the raw data. That's where the connected sensors, cameras and other data collection technologies that make up the Industrial Internet of Things (IIoT) and that are increasingly being integrated into the modern production environment come in. Many of these sensors will be collecting socalled ‘dark data' or ‘wasted' data - data that has, until now, been impossible or commercially unviable collect.

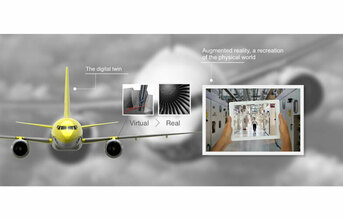

The ability to stream and analyze information from thousands if not millions of such sensors in a manufacturing environment in real time significantly improves the manufacturing intelligence available to an organization. What this ‘digital machining' approach means in practical terms is that it becomes possible to quickly and in a growing number of cases, automatically optimize and evolve production processes, predict failures, trigger maintenance operations, and automatically react to unexpected changes in production requirements. What's more, such benefits can be delivered without a reliance on the inhouse skills that have, until now, been essential in realizing even the most incremental manufacturing improvements.

(Continued on next page)