India's manufacturing story is entering a new chapter that is more ambitious, more technology driven and far more globally integrated than ever before. A new report by Boston Consulting Group and Z47 titled Digitizing Make in India 3.0 suggests that by 2047, India could lift manufacturing's share of GDP from about 17 percent today to nearly 25 percent powered by five strategic sectors. These include electronics, defence, automotive and EV, energy and pharmaceuticals which together could anchor a 25 trillion-dollar industrial opportunity.

It is a vision shaped not just by industrial growth but by a national aspiration. The report highlights a shift from assembly led expansion to technology led value creation. Flagship programmes such as Make in India, Atmanirbhar Bharat and the expanding network of PLI and DLI schemes have laid the foundation for this transformation by strengthening domestic capacity and encouraging innovation across the value chain.

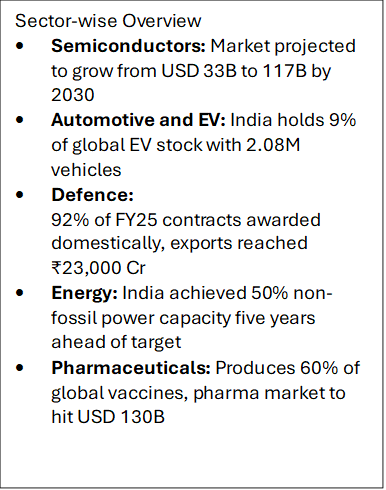

A major turning point is unfolding in electronics and semiconductors. India's semiconductor demand is projected to grow from $33 billion in 2022 to 117 billion dollars by 2030. This transformation is already visible. More than 99 percent of mobile phones sold in India are now manufactured locally compared to just 26 percent a decade ago. The shift shows how India has moved from being an assembly base to becoming a hub for design, innovation and deeper integration with global value chains.

Electronics and semiconductors are foundational to multiple end-sector with India's semiconductor demand projected to grow from $33 billion in 2022 to $117 billion by 2030. Ishang Jawa, Managing Director and Partner at BCG, noted, "This is not just about scale; it's about strategic self-reliance. India is no longer just assembling; it is designing, innovating, and integrating into the global value chain."

India's electric mobility story is advancing rapidly as well. EV sales have soared from 50000 units in 2016 to more than 2 million in 2024 giving the country nearly 9 percent of the global EV stock. With the right push India could emerge as a major exporter of EV components, wiring harnesses, power systems and other high value technologies creating an export opportunity estimated at 100 billion dollars.

Defence manufacturing, clean energy components and pharmaceuticals are also emerging as strong engines of growth. Each of these sectors benefits from a unique combination of policy support, rising domestic demand and the opportunity to integrate into global supply chains that are seeking diversified and reliable partners.

"India has an unprecedented opportunity to redefine its global position in manufacturing," said Natarajan Sankar, Managing Director and Partner at BCG. "With bold policy moves and accelerating demand in areas like EVs and advanced electronics, India is building both the foundation and the forward momentum to lead across sectors."

India's industrial rise will also be anchored by powerful regional clusters. From the electronics and semiconductor belt stretching from Noida to Chennai to Hosur to the emerging energy and technology hub in Dholera these corridors encourage co location of suppliers, shared testing labs, bonded logistics, skill hubs and faster innovation cycles. These ecosystems reduce costs improve competitiveness and accelerate time to market.

Talent will sit at the heart of India's manufacturing transformation. Mobilising PhD level innovators attracting researchers from global markets and creating stronger engineering and process training ecosystems will be critical for shaping the next generation of deep tech manufacturing. As highlighted in the report building a world class talent engine will enable India to realise its 2047 ambition and strengthen its position in advanced manufacturing.

To achieve this goal the report outlines four key imperatives for India. These include scaling R and D and intellectual property creation expanding design linked incentives building world class cluster ecosystems and deepening private sector and startup participation through stronger procurement pathways and growth stage capital.

India's momentum is real. But sustaining it will require significant investment in upstream capabilities risk capital and technology adoption. By embedding innovation and export readiness into its manufacturing strategy India can convert policy into long term global leadership and move closer to the vision of a Viksit Bharat by 2047.