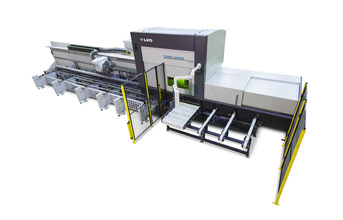

LVD Company nv has introduced the TL 8525 to its line of tube laser cutting machines. The new generation tube laser, designed from the ground up, comes equipped with several high-performance features to optimise tube cutting for even the most complex of applications. With a large 8500 mm infeed length, the TL 8525 can process tubes up to 250 mm round or square. Standard machine features include a 45-degree 3D tilt-axis cutting head for bevelling, 6-position front loader, and a wide X-axis cutting head range of 1190 mm to maximize material usage. A substantial 400 mm Z-axis permits the cutting of larger profiles.

A completely new design, its welded steel structure provides high rigidity and dynamics. The pre-mounted chuck and steady rest facilitate quick and easy machine installation and start-up. Because loading and unloading is handled on one side, the machine can fit in a small space or against a wall. To provide versatility for the widest range of use to cut round, square, rectangle, or other profiles, no matter the complexity, the TL 8525 is equipped with key features typically offered as options on comparable tube laser cutting machines. A 45-degree 3D tilt cutting head is standard. The multi-axis cutting head delivers high-precision bevel cutting in round, square, rectangular and irregular-shaped tubes, cuts complex profiles and channels, and can be used for weld-preparation cuts in thick-walled tubes.

A 6-position front loader is also a standard feature. This semi-automatic loading device provides a high level of material loading flexibility. It handles up to six tubes and offers six positions of even the largest diameter 250 mm tubes. The system can be loaded with different types of tubes in different sizes and can be interrupted during processing to add a new tube. Unlike a bundle feed system, there is no waiting to rebind the bundle in the loader, remove it from the machine and then reload a new bundle. The flexibility of material loading efficiently handles the needs of both small batch and long-run production. A generous 1190 mm X-axis cutting head range permits processing along a greater length of the tube, including behind the steady rest unit. The capability to process more of the tube and waste less material makes tube cutting operations more productive and profitable.

Other key features include a programmable table in the outfeed zone. The servo-controlled table features a tilt function for smooth part release and is integrated to a 3 m part evacuation conveyor. The conveyor uses multiple compartments to securely separate and hold parts - even round or longer tubes - as they move along the conveyor.

The TL 8525 incorporates a high degree of automation with automatic tube loading, automatic tube centring and automatic set up and adjustment of the chuck and steady rest. A high-power fume extraction system integrated to the chuck automatically removes approximately 4000 cubic meters of fumes hourly from the cutting area. It also comes equipped with a 2 kW IPG fiber laser source capable of cutting a range of ferrous and non-ferrous materials. A 4 kW laser source is optional. For more information, contact Tom Verhaeghe, tom.verhaeghe@lvdgroup.com