Optimizing overall equipment effectiveness (OEE) is a key to maintain productivity, ensuring work place safety and delivering the best return on investment. For air tool users in industrial applications, a correctly installed and maintained air supply system is a major contributing factor to OEE but one that can be easily overlooked and misunderstood.

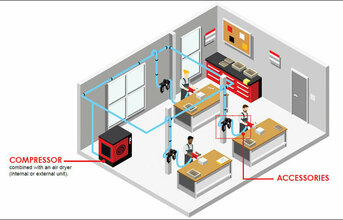

Most of the pressure drop occurs between the pipe-end and the tool. The choice of right airline accessories is critical to ensure the proper functioning of the tool. At Chicago Pneumatic, we educate customers the importance of right airline accessories through Airline Audits.

"Choosing the right tool for the job is only the first step in optimizing efficiency. However a proper air installation will ensure that tool achieves its desired performance. When it comes to air pressure, higher is not always better. It is important to maintain the right pressure and keep the pressure drops to a minimum to ensure high productivity. Right choice of accessories plays a major role in reducing pressure drop," says Priya Rajesh, Product Marketing Manager, Atlas Copco.

Priya Rajesh, Product Marketing Manager, Atlas Copco

"Chicago Pneumatic offers Airline Accessories Audit to measure energy loss in the airline. Through this audit we advise customer's correct design, installation and maintenance of airline accessories for optimum performance of the tool, higher energy savings and to reduce downtime of the tool," she adds.

END