S33 - for individual requirements

The S33 is designed for grinding in individual and series production and can be automated. Three grinding wheels ensure that the workpiece can be machined even more individually and quickly - complete machining in a class of its own! The wheelhead with motorized spindles can be equipped with two external and one internal grinding wheel in 10 different arrangements. The S33 has a B-axis with 1° Hirth gear.

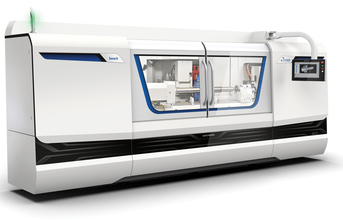

S31 - the versatile machine

The S31 is designed for grinding workpieces in individual, small batch and high volume production. It can be automated and, with its 16 different wheelhead variants, can be used for universal applications or for special tasks. The S31 boasts StuderGuide® guideways and the B-axis comes with fine adjustment.

The wheelhead can take up to three external grinding wheels or up to two internal grinding spindles in external/ internal combination. For high-precision form grinding, the machine is equipped with a workhead with direct measuring system and the StuderForm HSM software program. "We are delighted that we can now offer exactly the right machine for our customers who machine long workpieces," says Martin

Habegger, Project Manager at STUDER.

END