"iglidur I150 is extremely versatile and therefore also interesting for many other industries," explains Tom Krause, Product Manager for Tribo-Filaments at igus. "It is very tough and the easiest Tribo-Filament to work with. The material has an impressively high wear resistance at surface speeds of up to 0.2 m/s." In the igus test laboratory, iglidur I150 showed a much higher abrasion resistance compared to classic 3D printing materials for a large number of different test parameters.

Lubrication-free wear parts easily printed

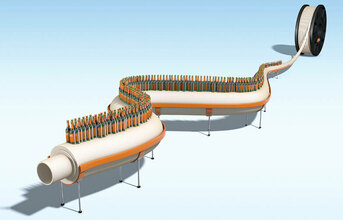

In addition to iglidur I150, the polymer specialist igus has five other lubrication-free and maintenance-free iglidur Tribo-Filaments for a wide range of applications - for example, where permanent load or chemical resistance is required. Common to all is that they are characterised by high abrasion resistance and are up to 50 times more wear-resistant than standard materials for the 3D print. The 3D print with the tribo-filaments from igus is a good option especially in the production of complex moving parts subject to wear in jigs and fixtures, in small batches and special machine construction. For customers who do not have their own 3D printer, igus offers a 3D printing service for wear parts, made from both the iglidur Tribo-Filament and its own laser sintered material iglidur I3. Customers can upload their data, choose the material, calculate prices and order their individual wear parts directly online.

END