Hexagon's Manufacturing Intelligence division has revealed new developments that advance the application of Directed Energy Deposition (DED) technologies to industrial applications, including collaborations with printer manufacturers pro-beam, Sciaky, DM3D, Gefertec and Meltio.

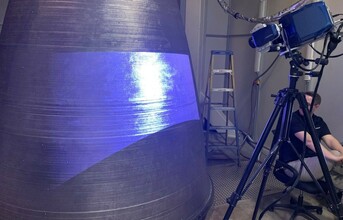

DED incorporates several metal 3D printing technologies used to produce parts by melting and fusing material as it is deposited. Applicable to a broad range of part sizes, it is attractive for the cost-effective production of large parts - from one to six or more metres - that may be impossible to manufacture using powder bed fusion (PBF) technologies. Indeed, SmarTech Analysis estimates revenues form large-format metal additive technologies and related areas will reach US $739 million in 2026.

Sharing core technologies with mature coating and welding processes, DED is rapidly gaining traction for military and aerospace Maintenance, Repair and Operations (MRO) because it can repair or rebuild high-end equipment, such as turbine blades. It also offers innovation potential within hybrid manufacturing processes, where it can add material and features to workpieces finished with wire EDM or milling processes.

Driven by interest from the aerospace and defence industries, parts are often made from high-performance metal alloys such as titanium and high-temperature and stainless steels. Hexagon is working with printer OEMs, customers and service providers to help predict how these materials behave when subjected to the thermal-mechanical stresses of DED processes, which are compounded in large structures.

"We see significant demand for the use of our technologies in tandem to create customised, cost-effective solutions that meet the needs of specific additive manufacturing technologies in a variety of applications," said Mathieu Pérennou, Global Business Development Director for Additive Manufacturing, Hexagon's Manufacturing Intelligence division. "Optimising deposition production processes may entail taking advantage of powerful simulation tools, state-of-the-art scanning technology, robust reverse-engineering and analysis software, or a combination of all of these technologies to achieve the required quality and repeatability.