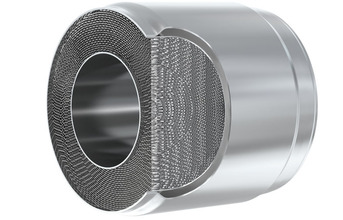

Continental's ring catalyst features an internal pipe running through the core and all the way along it provides the necessary additional length to allow better exhaust flow mixing. At the end of this pipe, the gas is redirected through 180°. Only then does it flow through the catalytically active portion of the catalyst, which surrounds the inner pipe like a sleeve.

"This way the annular catalyst extends the flow path without extending the overall length of the catalyst. This allows the catalyst to be placed close to the engine, so there is no increase in the time required to reach light-off temperature for converting NOx emissions," says Rolf Brück, Head of Catalysts & Filters Product Line, Fuel & Exhaust Management. "With this design, the swirl effect from the turbocharger wastegate gas actually assists exhaust mixing in the internal pipe."

The active section of the ring catalyst is wound from Continental's innovative LS metal substrate. The longitudinal structures in this material generate micro-level turbulence in the exhaust stream, which helps to direct the nitrogen oxides more effectively towards the catalytically coated catalyst wall, where they are converted.

END