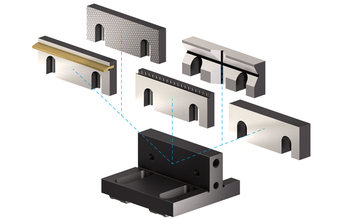

The Schunk Tandem TBA-D supporting jaw system transforms the Schunk Tandem plus clamping force blocks into multi-purpose powerhouses. For the first time it is possible to cover the whole clamping areas with clamping inserts from the Schunk standard chuck jaw program for stationary workpiece clamping. Instead of several different special chuck jaws, with the TandemTBA-D supporting jaw system, the user just needs a few standard inserts, which can be quickly configured and are usually available from stock. This reduces both the investment volume and implementation time to a minimum.

Standard interfaces allow different variations for raw and finished parts as an option including gripper jaws, stepped jaws, prism jaws, soft jaws, jaws with pull-down, jaws with T-nut, and many more. The supporting jaws are assembled with four screws at the base jaw of the clamping force block, maximising rigidity. With the fine serration, its position can be varied in just a few simple steps. The SCHUNK TANDEM TBA-D is available in three sizes for clamping ranges from 8 to 70 mm, 18 to 120 mm, or 30 to 200 mm. It is suitable for ID and OD clamping on SCHUNK TANDEM plus clamping force blocks in sizes 100, 160, and 250.

High clamping force and repeat accuracy

Schunk Tandem plus clamping force blocks develop high forces in confined spaces. Its one-pieced rigid base body, the wedge hook kinematics, and the long, ground jaw guidance provide concentrated clamping forces of up to 55 kN. They also ensure a repeat accuracy of up to 0.01 mm. This means that the clamping force blocks are also suitable for challenging milling processes with a high metal removal rate, high cycle times, and minimum tolerances. The optimised outside contour and minimum clearance prevent the nesting of chips, and keeps chips and dirt out of the clamping module. Tight-fitting screws ensure that the clamping module can be changed at a high repeat accuracy.

The standardised powerhouse is available in several varieties: pneumatic; hydraulic; with spring or manually actuated in module sizes between 64 and 250 mm with a standard stroke or long stroke; or as a clamping force block with a fixed chuck jaw. They are suitable for top jaws with tongue and groove, but also for jaws with fine serration. To learn more about the many possibilities, SCHUNK offers a free quick finder on their website www.schunk.com, which makes the search for the best clamping force block much easier. Five clicks is all it takes to find the tool suggestion for the matching modules.

END