Every machinist that works on aluminum knows the headache this alloy offers but its high strength to weight ratio make it an imperative and a highly popular material in the automotive and aerospace fields. The main problem in machining aluminum is the formation of built-up edges due to the adhesion of the materials used.

The primary tooling concern when machining aluminum that is minimizing the tendency of aluminum to stick to the tool cutting edge can be tackled with TaeguTec's new ChaseAlu XEVT line. It ensures good chip evacuation from the cutting edge, making sure the core strength of the tool is sufficiently durable in order to withstand the cutting forces thrust upon it without breaking.

ChaseAlu's two new offerings, the XEVT 16 - which is an upgraded version of the current XECT 16 - and the XEVT 22, come at a time when productivity, safety and cost needs to improve greatly for companies to be viable in today's increasingly competitive world.

Both types are designed with a stable "V" shape bottom as well as a unique "stopper" for rigid clamping and stability. Both sizes guarantee high precision and excellent surface roughness in aluminum and non-ferrous machining due to their high positive helical cutting edges and polished insert surfaces.

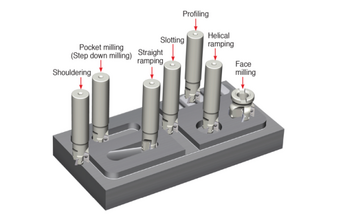

Both XEVT 16 and XEVT 22 inserts deliver outstanding productivity in demanding high-speed milling applications such as shouldering, slotting, face milling, step down milling, profiling, straight ramping and helical ramping. Moreover, both XEVT types are available in several corner radii and the XEVT 16 inserts are interchangeable with the current TE90XE and TFM90XE cutters in order to enhance the productivity of current XECT 16 inserts currently being used.

The cutter's simple screw clamping design ensures for proper seating and rigidity during machining in order that the tool stays firmly in place when handling high feeds and speeds on aluminum and non-ferrous materials.

Cutters are available in end mills, modular types, face mills and HSK type face mills.

In extensive tests, TaeguTec's ChaseAlu XEVT 16 clobbered the leading competitor's similar offering by increasing productivity by an amazing 329 percent while also increasing tool life by a very respectable 33 percent on an aluminum workpiece.

Contact: TaeguTec India P Ltd. Tel: +91-(0)80-27839111 Fax: +91-(0)80-27839123 E-mail: sales@taegutec-india.com