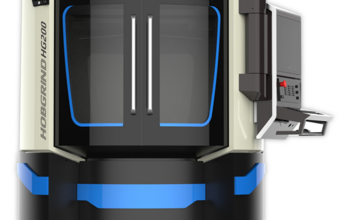

WIDMA® has launched Hobgrind HG200, a five-axis CNC machine dedicated to regrinding high-precision hobs and shaper cutters of both spur and helical types. This machine is ideal for gear manufacturers, especially those looking to perform regrinding operations in-house with end-to-end quality control, besides reducing inventory levels and lead time.

The new machine is built with thermal stability to ensure the hobs are ground to the highest precision levels. It has a combination of sleek and compact looks yet a robust structure. Weighing nearly 4.5 tons, Hobgrind HG200 has a cast iron base with special vibration dampening characteristics that enable smooth performance and ensure accuracy.

Hobgrind HG200's work head (A-axis) has a direct drive through a high-torque motor coupled with a high-resolution encoder for precise indexing of the component. Its tailstock holds hobs on mandrels between the centre is pneumatically actuated for quick change while ensuring rigidity. The optional motorised wheel dresser allows the dressing of the grinding wheel on the machine and a high degree of accuracy on the reground profile for the hobs with higher helix angles.

Hobgrind's FANUC CNC system ensures best-in-class performance. Its special menu-driven software, e-Gris, is leveraged for hob and shaper cutter resharpening, having an operator-friendly interface. The machine has an in-built probe that checks the orientation of the hob before regrinding. Additionally, its hob inspection program developed for measuring the hob after grinding is as per DIN 3968 or ANSI/AGMA, including a measurement report.

The machine is configured with a direct drive grinding spindle operating at 11 kW peak power and a maximum speed of 9000 rpm. Ball screws for the three linear axes are directly coupled to high torque AC servo motors for precise and accurate movement. The machine also features roller type guideways to provide high rigidity and enable the linear axes to achieve a maximum rapid traverse speed of 20 m/min. The work head has an ISO 50 taper for component holding, and its swivel axis (B-axis) comes with a worm-drive arrangement and a high-resolution external encoder for direct feedback.

Precision, versatility and shorter cycle time help users reduce the regrinding cost of hobs and shaper cutters significantly. The hob inspection cycle on the machine checks the hob before removing it from the machine after regrinding.

The machine also comes with safety features, such as an automatic fire extinguisher and pneumatic counterbalance for the vertical axis and a brake on the vertical servo motor to ensure that the machine is safe in case of power failure.