The two established geometries F57 (‘The universal one') and D57 (‘The stable one') are being supplemented with the addition of two new geometries: The A57 (‘The special one') for unfavourable machining conditions and high feeds, and the D51 (‘The quiet one'), which has an anti-vibration geometry for long projection lengths. The clearance angle of all variants is 15°.

The overall geometry is therefore always highly positive. That is why the cutting forces and, consequently, the power requirement, are reduced, which is an aspect that is particularly accommodating to operators of less powerful machines.

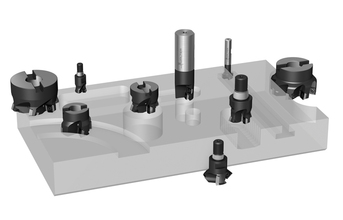

Set-up time is no minor consideration in terms of costs, but with M4000 tools, this concern is reduced to a minimum

The different geometries are identified by the presence, or absence, of a particular design of wave profile along the flank face. For example, A57 = no wave, D57/D51 = one wave, F57 = two waves. That makes it easier to identify the indexable inserts and facilitates handling for the machine operator. Important information can also be found directly on the tool bodies themselves.

All M4000 milling cutters, even those with small diameters, carry laser-engraved lettering which provides important data on assembly parts and tightening torques. Wolfgang Vötsch explains: "These clearly visible identification markings save tool managers a huge amount of time, because it means they do not have to first refer to their documentation when they want to prepare tools in readiness for use or put them back into stock again afterwards."

For more information: www.walter-tools.com