Later he graduated from BITS Pilani and did his MSc at MIT in Boston. But the boarding school discipline has stayed with him. "When you are in a military school, there is very little room to manoeuvre the system and I think that discipline has stood me in good stead all my life.

It has made me a very simple, straightforward kind of person. That also gets me into trouble sometimes as I am too candid, but by and large I think people appreciate the openness and integrity behind it. And as for machines, I was somehow always very mechanically minded. I liked machines right from my childhood, their feel, to be around them."

This love for machines has made him a hands-on leader right from 1972 when he first took to the factory's shopfloor. At that time, it was a small company struggling with labour-intensive operations and primitive technology. Although, he was given the charge of sales, Baba Kalyani's foresight told him that unless BFL adopted advanced technology, procuring new sales orders would be going down the drain.

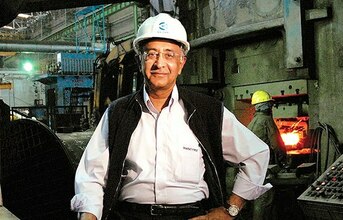

So he turned his focus to manufacturing and that is when it all started. Always to be seen the first and last on the shopfloor, Baba Kalyani propelled a struggling business into a global manufacturing giant. By the way, don't be surprised if you see him on the shopfloor even today in the company uniform just like any other employee.

It is this passion that has enabled Kalyani to take Indian manufacturing to great heights. Today, as India stands on the verge of a manufacturing revolution with our PM's call for ‘Make in India', Kalyani has already laid the foundation by making ‘Made in India' a brand to reckon with in the global market place.

Bharat Forge is today amongst the world's largest forging companies with manufacturing facilities spread across India, Germany and Sweden. It manufactures a wide range of high performance, critical and safety components.

In fact, the Mundhawa factory is the world's largest and most technologically advanced forging facility, with a capacity of 365,000 tonnes.

|

At the forefront of aluminium component industry |

(Continued on the next page)