After every acquisition, while retaining the local management he starts off a 100-day integration programme during which the top management from both countries meet up and discuss things.

This includes even the basics like how to say hello and how to reply to an email! This takes care of any cultural differences that could lead to barriers or mistrust in the future. A regular three-day company integration meeting every year in November, to which managers come with their partners to participate in team-building activities in an informal environment makes the picture complete.

There is indeed a unique Indian approach that Baba Kalyani brings to his global operations and he takes great pride in his Indian roots: "Indians tend to work with very people-led sensibilities. I am pretty sure a very structured and formal business set-up does not have the right effect. An India-led operation has two things going for it: one, by nature Indians are people focused and two, Indians have a tremendous sense of dealing with diversity. We deal with it on a daily basis."

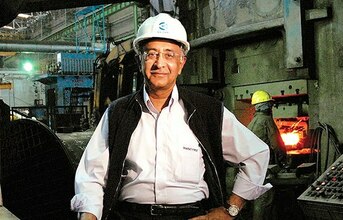

Kalyani's open-door policy at the Mundhawa factory located just outside Pune not only instils confidence in his employees but also keeps him in the know of the day-to-day operations. When your editor visited the factory some time back, he could feel the strong work ethic on the shopfloor of this very Indian factory that has a global edge to it.

In fact, there is an army cantonment like feel due to the discipline, the camaraderie, the focus and the determination on the shopfloor. And why not? Baba Kalyani did his schooling at the King George Royal Military Academy at Belgaum, a boarding school. And his vacations were spent at the Pune plant getting his hands dirty in the family business.

|

Strong global performance |

(Continued on the next page)