Reliable Performance

Patrick Ng is the chief designer of SRMS. He says: "The combination of an integrated optical measurement head, ball screw axes, servo-motors and encoded rotary table create an accurate, reliable and maintenance-free system. Unlike conventional probe systems, SRMS employs non-contact and optical inspection technologies to tackle the most typical seal-ring measuring problems faced by the industry. The choice of Renishaw was straightforward. We had experience of Renishaw's encoders from other successful projects in the past, so we knew their quality and how reliable they are. Renishaw's TONiC series encoders offer excellent immunity to dirt and its compact size and ease of installation provided us with a great deal of flexibility in system design. Two TONiC encoders are fitted onto the linear axes of the X-Y stage on SRMS and their excellent performance is surpassed only by their exceptional support."

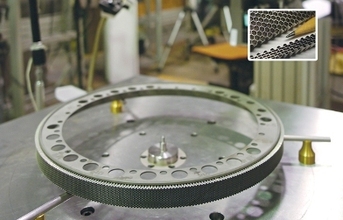

Ng continues: "Loading the ring in the correct position on the rotary table is critical, with a direct effect on the measurement result. We compared different brands but Renishaw's has the best cost-performance ratio. To ensure a smooth and stable rotation, it is important that the cyclic error is low and TONiC can achieve this."

Renishaw's TONiC RESM angle encoder system offers ultra-low cyclic errors of typically ±30 nm and a resolution up to 86.4M CPR (counts per rev) which satisfies many of the most demanding requirements. The high accuracy ring scale is designed with low mass and low inertia, allowing better dynamic performance while the readhead employs low noise (jitter) filtering optics to further improve positional stability and repeatability.

Ease of installation

All of Renishaw's ring scales feature a patented taper mount which minimises the installation errors and simplifies the integration. "The taper mount is one of the attractive features of Renishaw's encoders. It saves our time and reduces the workload in correcting rotor eccentricity," says Ng. In addition, every readhead features an innovative integral set-up LED which speeds up installation and removes the need for complex external set-up equipment, or oscilloscopes.