More options for distributed safety applications

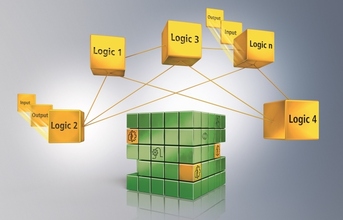

Just like the TwinSAFE Logic-capable I/O and motion products that are already available, the three new I/O modules can be used as controllers for the direct execution of customer-specific safety projects. A special feature is their communication capability, because like a dedicated controller, the safety project to be executed on the corresponding I/O component can establish direct communication relationships with other safety-relevant devices and preprocess the data internally. This makes it possible to implement highly granular machine modules with distributed safety applications. The central safety controller, if it exists in the application scenario, only needs to process the data that has already been accumulated.

The consistent hardware and software modularity of the TwinSAFE system simplifies the implementation of even very complex safety applications, and the combination of I/O and TwinSAFE control functionalities in a single I/O component makes it easier to distribute safety tasks across individual machine modules. It also reduces hardware costs. In terms of engineering, the customizing function speeds up the process and makes it more convenient. It also ensures minimum validation effort, which in turn further reduces the development costs.

More efficiency through customizing

Safety projects can be modularly designed in TwinCAT as usual. However, with the new customizing function, the operating modes "temporary deactivation", "permanent deactivation" and "passivation" can now be configured for each of these modules. With the corresponding configuration of replacement values for the interfaces between the different modules, users can thus implement highly complex, modular and scalable architectures while reducing their development costs. For example, a single safety project can be used for an entire family of machines by simply deactivating any modules that may not be needed according to the given requirements.

Source: BECKHOFF Automation Pvt. Ltd.

END