Our solutions

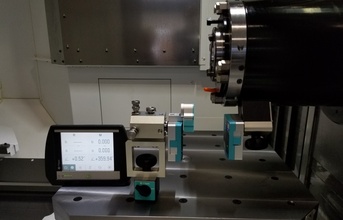

The MEAX system from Acoem is a innovative solution to make the task of checking the geometry condition in machine tools in an easy, accurate and fast way. The system uses different measuring sensors in combination with a handheld display to record, evaluate and document the geometric condition. Measurments like levelling, straightness, angular deveation, spindle direction, coaxiality, squareness, run-out, parallelism can all be performed with the MEAX system. The handheld display unit has a graphical user interface that guides the user throughout the different procedures making it usable even for non-experts. The MEAX system is highly flexible and can be used in varoius machine types, lathes/turnings centers, milling machines, machining centers, grinding machines, etc.

All the sensors in the MEAX system use wireless connection to the handheld display unit making it possible to use while the machine doors are closed, making it safe to operate without compromising any safety regulations.

The graphical presentation of the results makes it easy to interpret and clearly shows direction and amount of errors. The system can show measuring values live when performing mechanical corrections resulting in considerable times saving compared to traditional methods.

Additionally, results can be saved on the handheld display unit, making it easy to produce a measuring protocol on-site. It's also possible to transfer the results to a database to keep track of the historical data for all measurements in different machines. The MEAX system is especially designed for geometry checks in machine tools and the software is developed to follow the type of measurements described in ISO-standards (e.g. ISO 13041-1, 13041-2, 10791-1, 10791-2, etc.)

Source: ACOEM Group