Production flexibility and automation

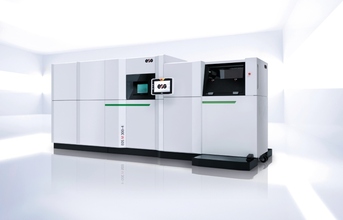

This new modular platform comes with a configurable and scalable equipment architecture, which enables full flexibility and customized system configurations. As such, it is the perfect choice for organizations demanding reliable and robust industrial standard equipment for AM production.

For better production flexibility and automation - and depending on system configuration - customers can choose between different solutions: one, two or four lasers, multi power laser configurations (400 or 1,000 Watt), fixed or variable focus, different types of recoaters, new and expanded exposure strategies, part handling (manual or automated), monitoring options and three different clamping systems (3R, Delphin, Erowa). Customers can also flexibly choose between two powder dosing options for full build jobs without refilling: bottom-up dosing to become independent of materials particle size distribution; and automated, top dosing to enable a closed loop solution.

The system will be compatible with the EOS Shared Modules in which manual or automated peripheral modules and transport logistics supply several EOS metal AM systems. As a result, all set-up, unpacking, transportation and sieving actions will be carried out independent of, and parallel to, the AM build process.

Productivity increase by factor 4 to 10

The EOS M 300-4 with four lasers will be able to offer variable laser power sources in the future - from 4 x 400, to a mixed set-up of 2 x 400 and 2 x 1,000, up to 4 x 1,000 Watt laser power. The system also offers full field overlap with four scanners, meaning that lasers can reach all spots on the build plate, enabling full flexibility with regards to build orientation. The system enables an increased productivity by factor 4 to 10 compared to the EOS mid-frame system EOS M 290, dramatically reducing cost per part.

(Continued on next page)