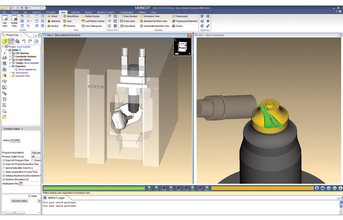

Opting for the right machine using virtual simulation

The aerospace manufacturer working on the leading edge took the idea a step further. After proving the 5-axis milling process could work, they were ready to order production machines. Rather than simply picking the machine from a catalog, they designed the machine in their simulation software, where they had already proven the process would work. These files were then sent to the machine tool builder who built the machine exactly to their specifications as described in a virtual machining simulation.

Another leading aerospace company created programs for more than 200 parts and proved them using virtual simulation software even before the arrival of machines on their shop floor. All the machines ordered were built using virtual simulation software and all NC programs were proved on a virtual machine. The machine loading plan was also prepared, thanks to accurate cycle times provided by simulation software. Once the machines arrived, they cut the parts without any further delay.

Summary

By maximising the use of simulation software, shopfloors don't need to wait for NC programs. There are always opportunities to improve an existing process, and simulation software can help by giving the NC programmer the freedom to try practically any machining technique in a virtual world. Only creativity and a good virtual platform are required to accomplish the job!

END