Measuring 1000 true 3D data points per second, the system's superior analytical capabilities provide unparalleled opportunities for workpiece measurement, inspection, adaptive machining and on-machine process control, whilst optimising machine utilisation and cycle time. This new scanning technology opens up new process control methods not previously possible with other measurement methods.

In parallel to extremely fast and accurate 3D measurement the Sprint scanning system has also been designed to facilitate automated process control with no requirement for operator intervention.

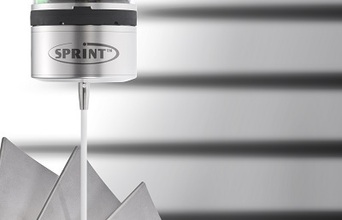

Incorporating multiple patented technologies, the Sprint system enables unrivalled high-speed, high-accuracy 3D surface data collection through powerful compensation of the static and dynamic volumetric errors which are often associated with high-speed machine movement.

The Sprint system is a ground-breaking high-speed, high-accuracy tool with an exceptional range of potential applications, enabling a wide range of measurement and process control methods, reducing scrap and rework, while increasing machine capacity by reducing measurement cycle times.

More information can be found at www.renishaw.com/SPRINT