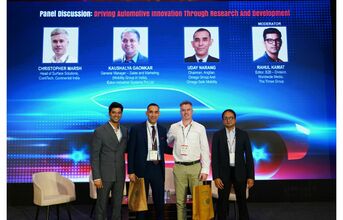

Researchers are working on creating lightweight and durable materials that help cars achieve efficient fuel consumption. New R&D initiatives also focus on making plastics that can be recycled, reducing the environmental impact of vehicles, and are also figuring out how to use plastics to make cars smarter and safer; against this backdrop, the conference divide into a panel discussion on ‘Driving Automotive Innovation through Research and Development'. The session was moderated by Rahul Kamat, Editor, B2B Division, Worldwide Media, and comprised of Christopher Marsh, Head Surface Solutions, ContiTech, Continental India; Kaushalya Gaonkar, General Manager, Sales and Marketing (Mobility Group in India), Eaton Industrial Systems Pvt Ltd., and Uday Narang, Chairman, Anglian Omega Group and Omega Seiki Mobility.

This discussion began as Kamat asked Christopher to share his views on the difference with which people perceive R&D in international markets and Indian markets.

Marsh responded that having spent five years in India, he perceives no significant difference. He noted that Prime Minister Modi introduced the ‘Made in India' initiative, and in Marsh's observation, India has progressed to a stage where the term could be replaced with ‘Engineered in India.' Today, many technologies are not just manufactured but also developed within the country, with numerous companies establishing excellence centres here. According to Marsh, the key disparity lies in the haptics—the tactile and sensory experience. He pointed out that while the product quality may be comparable, the touch and feel, especially with premium car manufacturers in Europe, differs significantly from the standards in India.

According to him, the interior stands as the second most crucial design element in a vehicle. When a customer opts for a car, the initial focus upon opening the car door is directed towards its interior. In this domain, India is still undergoing developmental strides.

He added that while discussions often revolve around price sensitivity, it's essential to recognise that this concern is not exclusive to India. It prevails across various markets, be it the US or Europe. There's a need for a shift in perception, emphasising a balance between sustainability, quality, and cost. Adopting a philosophy encapsulated by the three Ps—People, Planet, and Profit—can guide this approach.

Turning to Uday, Rahul indulged him to share his views on the point of process management and asked whether they have been borrowed by the Indian market from the western countries. Narang agreed that price sensitivity is everywhere, but the price sensitivity here is different from the price sensitivity in the other markets, but ‘Make in India' doesn't mean that we don't learn from their experiences, successes, and even failures. He stated that processes are in a state of evolution, guided by a "think global, act local" perspective. The approach must be to assimilate knowledge gained worldwide and implement it locally by building and developing in India. Consequently, in terms of processes and systems, he encouraged Indian manufacturers to adopt a longer-term perspective. He adviced to not merely meet immediate needs but to explore the wonderful opportunities presented globally. With a youthful population, abundant opportunities, and a vast market, the suggestion is to shape the country through engineering, using processes, and promoting the ‘Make in India' initiative.

Continue Reading on Page 2