When Ford's EcoBoost-powered race car hits the track at the Belle Isle Grand Prix this weekend it will be using engine parts made by a computer printer.

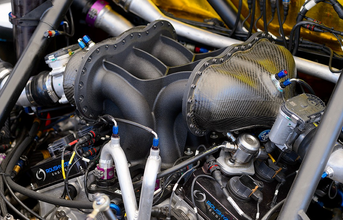

Using an innovative new technology called 3D printing, parts such as the intake manifold on the Ford EcoBoost race engine used in the Chip Ganassi Racing with Felix Sabates Daytona Prototype car are now created on a printer.

"3D computer printers have totally changed the development process for our Daytona Prototype race cars," said Victor Martinez, 3.5-liter EcoBoost race engine engineer. "3D printing has advanced at such lightning speed in recent years that in a matter of hours, we can create real, usable parts for race cars. That's exactly what we did for the 24 Hours of Daytona earlier this year."

From road to track, 3D printing accelerates Ford product development

Ford first started to 3D-print decades ago, purchasing the third 3D printer ever made, in 1988. The company first used 3D-printed parts for prototype buttons, switches and knobs. As the technology has improved, the quality of 3D-printed parts has become remarkably precise, and the parts themselves have become increasingly usable.

So smooth and precise has the finishing process become that 3D-printed parts are now used in real-world settings - on prototype vehicles built for durability testing, and on the Ford race car that won the 53rd running of the grueling 24 Hours of Daytona in January.

Ford's rapid prototype lab: Where product development never stops

In the competitive world of endurance racing, the push for increased reliability and horsepower never stops and, in Ford's rapid prototype lab, it doesn't have to.

"We have the ability to design an entirely new part and, one week later, have that part in hand," said Martinez. "This lets the engineers who develop our cars - both for road and track - spend more time testing, tuning and refining."

Continued to next page