Han-Eco B: Industry standard in plastic

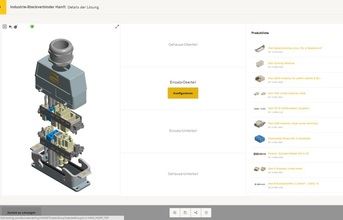

HARTING has taken a big step forward with the Han-Eco®: the connector series with its high-performance plastic housings is now fully compatible with the industry-standard Han® B. Consequently, all contact inserts and modules which can be integrated into the standard metal housing also fit into the corresponding Han-Eco® B housings. Plastic and metal versions are plug-compatible.

This ensures full backwards compatibility of the Han-Eco® B in industrial environments. Users can take advantage of the plastic and/or metal materials as part of their associated cost and quality requirements. Existing manufacturing test facilities remain usable for both housing variants.

The use of plastic also increases corrosion resistance. The high-performance plastic employed is fire-resistant to UL94 V0 and reduces the housing weight by roughly half compared to metal.

In addition to the use of standard monoblocks, it goes without saying that it is also possible to use the Han-Modular® product range via the hinged frame. The metal hinged frames can be firmly screwed into the new housings. The Han-Eco® series achieves full compatibility across the entire Han® portfolio.

"We have achieved the goal of designing Han-Eco® and Han® B standard-compatible," says Product Manager Ingo Siebering. The user benefits from total flexibility in selecting the connector material used to connect components and equipment in a machine, plant or within a production scenario.

(Continued on next page)