Values of Additive Manufacturing

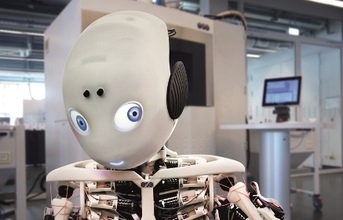

Additive Manufacturing allows for highly complex structures which are also extremely light and stable. It provides a high degree of design freedom, optimization and integration of functional features, and the manufacture of small batch sizes at economical unit costs. The Roboy development benefits from all these advantages: Building complex functional geometries without classical fabrication constraints allows the Roboy team to implement functionality directly into the geometrical parts.

Consequently, build complexity is reduced, and many of the otherwise necessary assembly steps can be dispensed of. For example, Roboy's hands and forearms are manufactured in one piece, including several joints and individual phalanxes for each finger.

Due to Roboy's maximal mechatronic complexity on a minimal space, it is not possible to validate some project requirements in simulation. Therefore, the development team needs to be able to test the robot itself. AM is key to this because it allows the fast manufacturing of individual components and the modularization and parameterization of the robot's construction, enabling an iterative hardware development.

Rafael Hostettler, Roboy project leader, comments: "In software development, rapid development cycles allow software improvement by testing it ‘in the wild'. Additive Manufacturing allows us to apply this approach to robotics, enabling a rapid development to find optimal functional parts in a fraction of the time." He continues: "EOS' AM technology is a key component for doing this as it enables the iterative hardware development that is crucial for our project."

(Continued on the next page)