CGTech and MachiningCloud have jointly announced a VERICUT enhancement in the MachiningCloud. How will this help your customers?

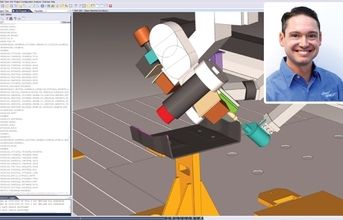

Setting up virtual simulation is much like setting up a job on the real machine. You need a stock model, a posted g-code program, fixtures, and tooling. VERICUT is now connected to the Machining Cloud, providing access to cutting tool models supplied by tool manufacturers world-wide.

The manufacturing industry is currently very interested in connected machines and leveraging the Industrial Internet of Things (IIoT). As more of the world's manufacturing resources become available via internet connectivity, CGTech will provide connections to these resources for our VERICUT users.

To address various market demands, composites are being used by a wide range of industries, particularly in the aerospace and automotive sectors. However, machining of composites is quite a challenging process. At the 2016 JEC Composites show, CGTech is demonstrating VERICUT Composite Applications. Tell us more about this.

VERICUT Composite Applications is a term we use to describe our suite of machine-independent off-line programming and simulation software for automated fibre-placement and tape-laying machines. It consists of three separate products that can be used individually or together: VERICUT Composite Paths for Engineering (VCPe), VERICUT Composite Programming (VCP), and VERICUT Composite Simulation (VCS).

You bring up an excellent point about the machining of composites. Composite parts, which are typically made from Carbon Fibre Reinforced Plastic (CFRP), can be manufactured in several different ways, but almost all the methods to create the part's shape involve a moulding or forming process. The moulded composite parts are sometimes moulded to net shape, but more commonly they are "near net shape," and consequently require additional removal processes such as trimming, some light machining, and maybe drilling.

By the time the part is at this stage, many hours have been invested and scrapping the part can be disastrous. Thus, to ensure the machining is correct, VERICUT simulation is used to simulate the NC programs. VERICUT can simulate conventional milling of composites, but can also simulate trimming with an ultrasonic knife or waterjet cutter, including specific checks for improper use of these technologies. CGTech has been supporting these kinds of machining operations with VERICUT for nearly 25 years.

(Continued on the next page)