System tools, i.e. those that can be used universally for numerous machining requirements, reduce the complexity of and susceptibility to errors in production, thus making it more cost-efficient.

The latest example of this product philosophy from the Walter Group is the new M4000 range with system indexable insert. Walter has consistently implemented the idea of a system concept: The new inserts and cutting bodies are manufactured in a way that offsets CO2 emissions.

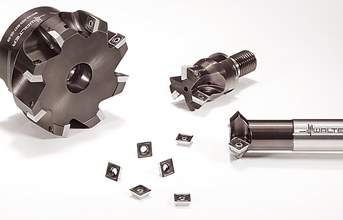

The M4000 - four square indexable inserts that can be used in three different types of milling cutters and master many common milling operations: For example, face milling, shoulder milling or chamfering in all steel, stainless steels, cast iron, and even difficult-to-cut materials.

M4000 inserts can therefore be used more universally than their specialised relatives in the Walter BLAXX and Walter Xtra▪tec ranges. However, just like its two cousins, it is coated with the high-performance cutting material Tiger•tec Silver.

Features of the system

Wave profile: The flank faces on the four cutting edges are provided with a wave profile, which displays the geometry of the indexable insert: The more waves that are visible, the more positive the geometry. The system indexable inserts have a positive basic shape with a clearance angle of 15 degrees. The effect: Less power is required for milling, energy consumption is reduced, and economic efficiency is increased. Currently the stable (D57) and universal (F57) geometries are available.

Applications can be extended: The M4000 mills can also accommodate special indexable inserts. For the M4002 high-feed milling cutter, there is a circumference-sintered insert with facet for improved surfaces. A special insert with a larger corner radius guarantees increased cutting edge stability when working with the high-feed mill and shoulder mill. For the M4132 shoulder mill in particular, an indexable insert with a fully ground circumference is available, which can also come with additional facets.

Ground support: As a result, the support in the tool body is more precise; the low vibration tendency increases the tool life. The rake face has markings to ensure unmistakeable orientation when changing the cutting edge.

(Continued on the next page)