Who likes to have greasy hands? You might know this from your children. They quickly eat a few fries and then wipe their greasy fingers on the T-shirt. Nobody likes to have greasy fingers or grease stains on their clothes. If you work with machine elements such as ball bearings, gears or linear guides, it is almost impossible to avoid this contamination, isn't it?

The fact is that all movements of metal on metal must be provided with a lubricating layer. Oils or greases are used for this purpose. If these are not present or are not relubricated regularly, the system will fail.

Grease thus ensures the function of a metallic bearing but can also be extremely troublesome in many applications. Have you ever seen a bearing getting corroded/getting failed because of inadequate lubrication or recirculating ball damaging the rails or shafts?

Isn't it a big worry for all engineers to find a solution to these problems?

You would love to know that drylin linear bearing has already resolved millions of existing conventional bearing problems like corrosion, Noise, Weight reduction and many more. It is also 1:1 interchangeable with conventional recirculating bearing.

Let's see the working of igus' drylin linear bearing.

drylin® T slides instead of roll

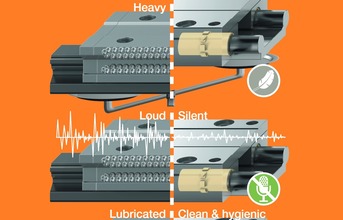

The igus drylin® linear bearings enable maintenance-free and lubrication-free operation of parts of machines and equipment whose function is determined by relative movements in a straight line between components. The special dry-tech® high-performance plastics of the bearing bushings ensure machine elements can be moved along a shaft or profile guide silently and with little friction. Compared to linear solutions with rolling elements, the acquisition costs are up to 40 per cent lower, and there are no additional operating costs.

One or several rows of balls support the shaft in linear ball bearings. To work properly, they need a ball recirculation system that guides the balls back in the direction opposite to the shaft's direction of movement. The ball recirculation system and the high-stress level on the balls due to the load being applied to a small point on each ball result in potential weak spots and noise. Recirculating ball systems can be replaced with igus® linear bearings of the drylin® series in nearly all areas of use. Due to their simple structure, the drylin® linear plain bearings have very little susceptibility to failure. Lubrication-free operation means that the machine parts remain free of dirt, dust and moisture. Another advantage is the very quiet operation of the drylin® linear bearings.