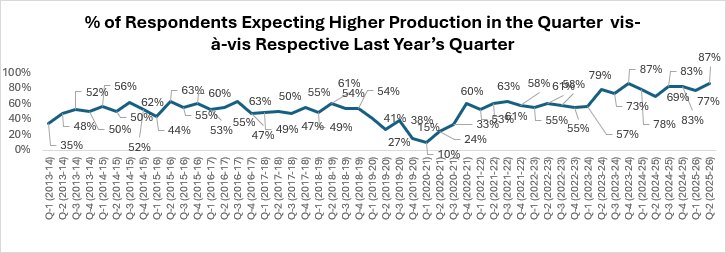

FICCI's latest Quarterly Survey on Manufacturing indicates a sustained growth and increasing optimism for India's manufacturing sector. In comparison to Q1 FY 2025-26, when 77% of respondents reported higher or same production levels, approximately 87% of respondents reported either higher or same production levels in Q2 FY 2025-26, noted the FICCI Survey. This is one of the highest percentages witnessed in the last many quarters. This optimism is also evident in domestic demand, as 83% of respondents anticipate an increase in orders in Q2 FY 2026 compared to the previous quarter and more so after the latest GST rate cuts announced.

FICCI's latest Quarterly Survey on Manufacturing (QSM), which is the 67th edition of the survey, assessed the performance and sentiments for Q2 July-September 2025-26 of manufacturers for eight major sectors namely, Automotive & Auto Components, Capital Goods, Chemicals, Fertilizers & Pharmaceuticals, Electronics, White goods & Telecom, Machine Tools, Metal & Metal Products, Textiles, Apparels & Technical Textiles and Miscellaneous. Responses have been drawn from manufacturing units from both large and SME segments with a combined annual turnover of over Rs. 3.0 lakh crores.

Source: FICCI survey

Capacity Addition & Utilization

- The existing average capacity utilization in manufacturing is close to 75%, which reflects sustained economic activity in the sector.

- The future investment outlook is also positive, with over 50% of respondents indicating plans for investments and expansions in the next six months.

- Challenges faced by respondents in expanding capacities include global and geopolitical factors (tariffs, trade restrictions, economic uncertainty), operational issues (labour availability, raw material shortages, regulatory challenges), and others.

- The table below gives average capacity utilization for various sub-sectors of manufacturing:

Table: Current Average Capacity Utilization levels as reported in survey (%)

|

Sector |

Average capacity utilization (%) |

|

Automotive & Auto Components |

75 |

|

Capital Goods |

70 |

|

Chemicals, Fertilizers & Pharmaceuticals |

71.5 |

|

Electronics & Electricals |

70.0 |

|

Machine Tools |

77 |

|

Metal & Metal Products |

75 |

|

Miscellaneous |

78 |

|

Textiles, Apparels & Technical Textiles |

75 |

|

Average |

75 |

Inventories

- In Q1 and Q-2 2025-26, more than 90% of the respondents reported higher or same level of inventory.

Exports

- In exports, about 61% respondents reported higher or same level of exports in Q1 FY 2025-26 and in Q2 2025-26 more than 70% of the respondents expect their exports to be higher or same as compared to previous year's similar quarters.

Hiring

- 57% of the respondents are looking at hiring an additional workforce in the next three months.

Interest Rate

- The average interest rate paid by the manufacturers has been reported to be 8.9%. A little over 81% of respondents reported sufficient availability of funds from banks for working capital or long-term capital.

Sectoral Growth

- Based on expectations, the likely sectoral growth range is shown below:

Table: Growth Expectations for Q-2 FY 2025-26*

|

Sector |

Growth Expectation |

|

Automotive & Auto Components |

Strong to Moderate |

|

Capital Goods |

Strong |

|

Chemicals, Fertilizers & Pharmaceuticals |

Moderate |

|

Electronics & Electricals |

Strong |

|

Machine Tools |

Strong |

|

Metal & Metal Products |

Strong |

|

Miscellaneous |

Moderate |

|

Textiles, Apparels & Technical Textiles |

Moderate |

* Very Strong >20%; Strong 10-20%; Moderate 5-10%; Low < 5%; Source: FICCI Survey

Production Cost

- Production costs for manufacturers in Q1 and Q2 FY 2025-26 seem to remain on higher side. Over 50% of respondents reported an increase in the cost of production as a percentage of sales, which is consistent with the previous quarter's findings, indicating that costs are still on the higher side.

- The increase in cost of production compared to last year is mainly due to higher raw material costs including key components, bulk chemicals, metallurgical coke, and iron ore along with rising labour expenses and increased logistics, power, and utility costs.

Workforce Availability

- Most sectors though are not facing shortage of labor at factories as less than 80% respondents mentioned that they do not have any issues with workforce availability, the remaining 20% feel that there is still lack of skilled workforce available in their sector and there is a need to step up efforts both at government and Industry level.