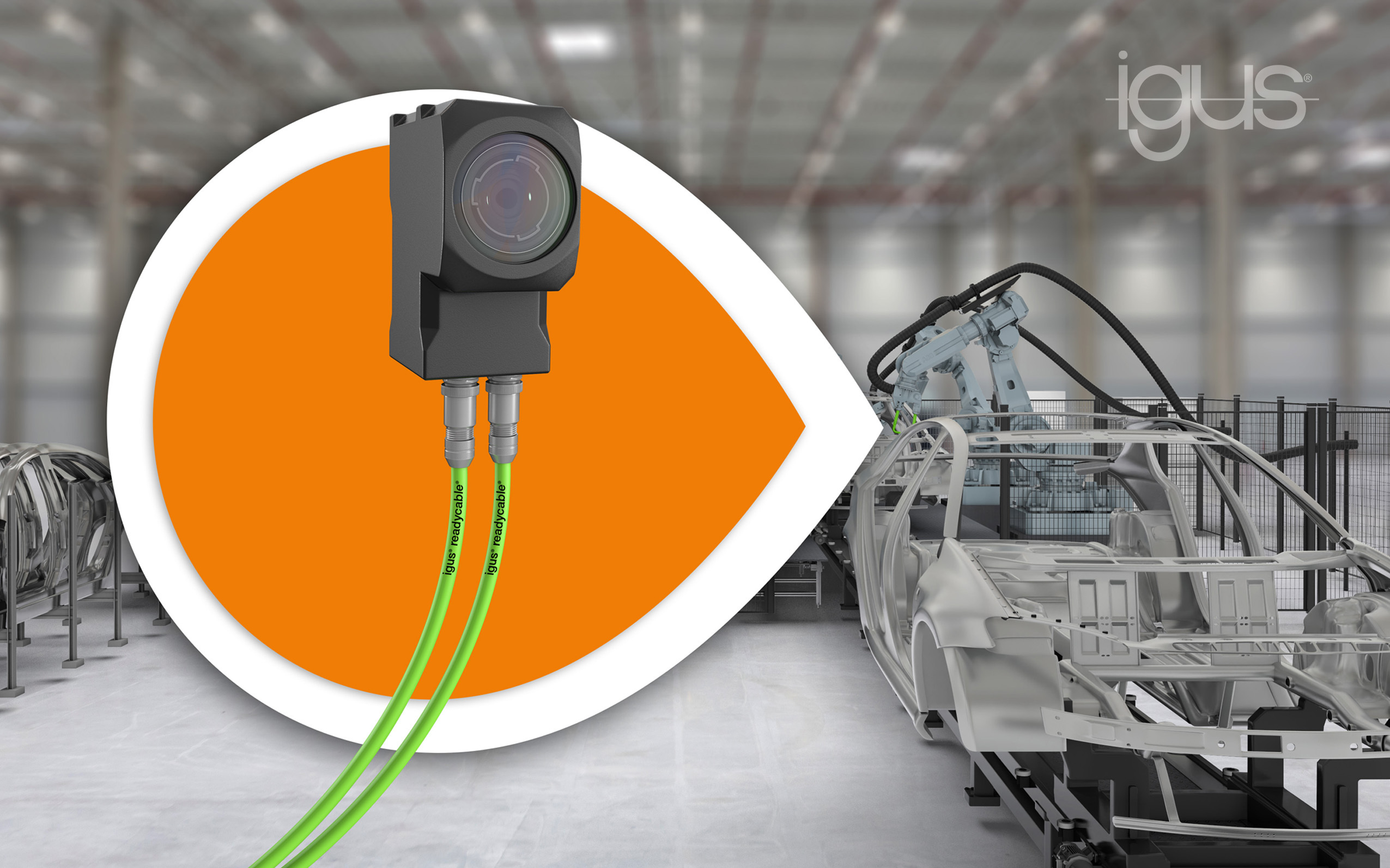

igus is expanding its range of harnessed readycable for moving industrial applications. New additions to the portfolio are cables with plug connections for systems from Keyence, one of the world's leading manufacturers of automation and quality assurance solutions. Designers can immediately connect the ready-to-connect cables to moving high-speed cameras using the plug-and-play principle, for example, and thus make them even more fail-safe - without time-consuming and error-prone in-house designs.

A car manufacturer is testing a new high-speed camera system in production. As car body parts pass by on the conveyor belt, the camera moves along on one axis and checks seams in real time. But then the camera's data cable fails. The continuous movement was too intense and caused a cable break. "In such moving applications, the cables are under considerable stress due to the travelling speed, the bend radius or the ambient conditions - and are therefore often the first components to fatigue or fail. The consequences are high downtime and maintenance costs," says Markus Hüffel, Product Manager readychain and readycable at igus. Designers then often start experimenting with cables from different manufacturers in order to find solutions. However, this takes time and is prone to errors because establishing a plug connection to the camera system alone can be complex. "With our readycable portfolio, we therefore offer robust cables especially for continuous movement, which we supply ready for connection and tested with the appropriate plug connection," says Markus Hüffel.

Plug-and-play: Configure Keyence-compatible cables online

New additions to the readycable range are energy and data cables for vision systems from Keyence. The company is a leading global manufacturer of automation and quality assurance solutions and is accordingly relevant for design engineers. At igus, they now have the opportunity to find the right pre-fitted energy and data cables for their individual application. With the readychain service, design engineers can go one step further. Because igus not only supplies readycable, but also completely ready-to-install energy chain systems, so-called readychains. E.g. in the form of a three-dimensional e-chain from the triflex series, which reliably follows the dynamic movements of robot arms thanks to its round chain links. "This combination promises maximum reliability for moving camera systems. And at low cost and with short delivery time - all from a single source, tested and guaranteed.

readycable factory in Cologne: over 10 million metres of cables per year

At its headquarters in Cologne alone, igus produces over 10 million metres of its chainflex cables every year. Over 200 automated machines are used, including extruders, winding and testing stations as well as systems that implement the plug connections for readycable harnessing. To guarantee reliability, all cables are 100 per cent electrically and mechanically tested in the igus test laboratory. The special feature: The data from the test laboratory is fed into an online service life calculator, which predicts the service life of the cables in double strokes by specifying the application parameters. The cable is then delivered by igus within ten business days, cut to the required length and equipped ready for connection with the right connectors to match the existing Keyence camera system. Thanks to this quality assurance and the numerous data from the test laboratory, the company even offers a unique four-year guarantee on its products with online service life calculation.

The ready-to-connect readycable cables with matching Keyence plug connections increase the reliability of vision systems, for example for quality control in automotive production. (Source: igus GmbH)