As India's manufacturing sector continues to evolve, there is a strong push toward lean production, digital transformation, and smarter automation. From small job shops to large-scale production lines, businesses are actively seeking solutions that help them improve efficiency, reduce waste, and stay competitive in a fast-changing market. Renishaw India is proud to support this journey by offering accessible, reliable, and intelligent metrology solutions that simplify automation and deliver measurable results.

At ENGIMACH 2025, visitors will have the opportunity to experience how the simplest form of automation can make a big impact. We will showcase a comprehensive range of process control technologies, including pre-process machine calibration, in-process probing and post-process measurement both online and offline.

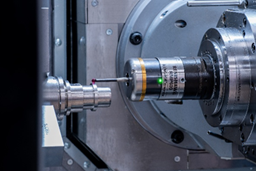

Comprehensive range of probing and tool measurement systems for CNC machine tool which are designed to improve machining accuracy, efficiency, and automated systems deliver significant cost savings and quality improvements. Our probing and tool setting systems help manufacturers to reduce scrap rates, eliminate machine down-time, and improve component quality.

It enables automated component set-up, in-cycle gauging, tool setting, and broken tool detection. When coupled with automatic offset updates, our technology enables you to machine with confidence, reduce set up times, and improve process control

Renishaw will display the Equator™ gauging system which plays an integral part in supporting manufacturers' drive to develop their own smarter processes and embrace factory automation. It can operate at a temperature of 5-50°C and up to 80% humidity, optimised for part loading via robot or shuttle system. To control manufacturing processes, gauges, such as sets of callipers, go / no-go gauges or bore gauges, have been used for decades. The Equator system is an innovative flexible gauge designed to provide speed, repeatability and ease of use for manual or automated applications on the shop floor. With the help of additional IPC software, the Equator gauging systems can apply automatic offset updates, compensating for common causes of process instability, such as tool wear and thermal drift. Its built-in Process Monitor software makes part-to-part inspection results instantly visible via a status monitor bar graph and feature table.

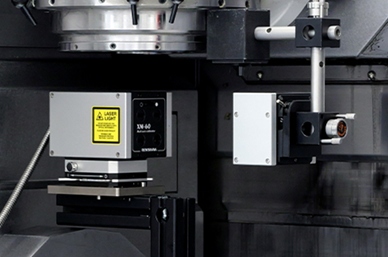

In the series of innovation visitors can explore the XM60 multi-axis calibrator measures all six degrees of freedom from a single setup, helping manufacturers quickly identify and correct machine errors. This ensures machines are performing at their best, supporting high-precision manufacturing and ongoing performance monitoring.

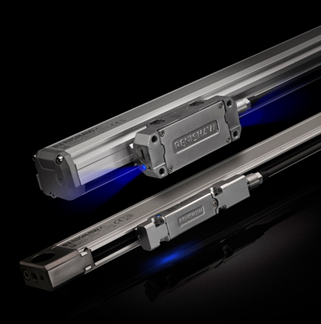

Featuring the FORTiS encoder series which provides robust, high-performance position measurement in demanding environments. Its non-contact design and advanced sealing technology ensure reliable feedback, process stability, and reduced maintenance for machine tools.

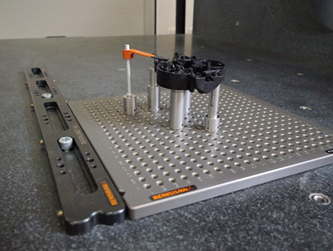

Styli flexible, repeatable setups for inspecting complex parts are helping manufacturers reduce setup time and improve throughput. Renishaw's fixturing systems are making quality control easier and more efficient, supporting the industry's shift toward smarter workflows.

To further enhance visitor engagement and knowledge sharing, Renishaw India will feature its Digital Interactive Display (DID) at the booth. The DID will provide a hands-on experience, to educate our visitors on the need for probing systems in their CNC machines.

Renishaw's technologies are designed to help manufacturers, reduce process variation and achieve consistent, high-quality output. Automate routine tasks and minimize human intervention, addressing skills shortages and enabling "lights out" manufacturing. Increase throughput and asset utilization, allowing more parts to be produced with fewer machines and lower labor costs. Shorten lead times and improve delivery schedules by streamlining setup, inspection, and feedback loops.

Whether you're working with complex components or managing high-volume production, Renishaw's technologies are designed to adapt to your needs and scale with your growth.