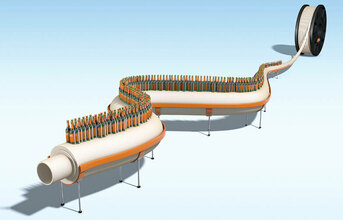

The 3D print material iglidur I150 developed by motion plastics specialist igus has now been approved for food contact according to EU regulation 10/2011. By the certification of this Tribo-Filament that has a versatile use, customers can now print their custom-made parts which are approved for direct contact with food or cosmetics in moving applications. The material is lubricationfree and maintenance-free and can be used even on 3D printers that do not

have a heated printing plate.

With the certified iglidur I150 Tribo-Filament, lubrication-free special parts for movement in the food industry can be produced quickly and

cost-effectively. iglidur I150 can be processed on any 3D printer where the nozzle temperature can be set to 250°C. Since the high-performance plastic has a very low shrinkage, it can also be processed on 3D printers that do not have a heated printing plate. In this case, the igus adhesive film is recommended as the base for the print bed in order to ensure good adhesion.

(Continued on next page)