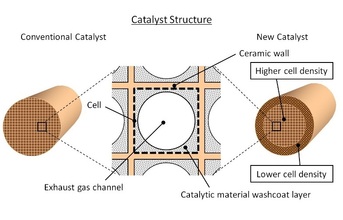

Toyota Motor Corporation has announced the commercial availability of a new, smaller catalyst that uses 20 percent less precious metal in approximately 20 percent less volume, while maintaining the same exhaust gas purification performance. The design is the world's first integrally-moulded Flow Adjustable Design Cell (FLAD) substrate, with a different cell cross-sectional area at the inner portion compared to that at the outer portion. Innovative design and manufacturing technologies have allowed for the mass production of the new catalyst, which will gradually be installed in new vehicle models, starting from the Lexus LC 500h later this year.

Increased usage of catalytic precious metals to clean exhaust gas and improve air pollution issues present many issues, including increased costs and resource depletion. Toyota has conducted extensive research and development into finding solutions to help improve the purification efficiency of catalytic precious metals, such as finding the optimal substrate shape and length, as well as modifying the cell wall thickness and cross-sectional area. Other R&D efforts include selectively washcoating precious metals and other catalytic materials, and changing catalytic substrate cell density in line with exhaust gas flows.

Toyota and Denso Corporation have developed this new FLAD substrate to improve the uniformity of exhaust gas flow. Through a series of validations using simulations and prototype substrates, both companies have succeeded in improving uniformity of exhaust gas flow within the catalyst by optimizing factors such as the ratios of cross-sectional areas of cells at the inner and outer portions, and their corresponding densities. As such, with this development, approximately 20 percent less precious metal is used in a more compact catalyst that contains approximately 20 percent less volume, while maintaining the same exhaust gas purification performance as that of conventional catalysts. The newly developed innovative design and manufacturing technologies have also allowed for the mass production of the world's first integrally moulded catalyst.

END