There is always a need for generalpurpose machine shops. These are companies, often family-owned, that make a specialisation out of being generalists. Usually they do not have their own product lines; they do not even have a preferred industry sector or a technology that sets them apart from other shops. What they do have, however, is their reputation. G-Tech CNC, based near Reggio Emilia, Italy is one of them.

"We are here for what the market needs, when it needs it," says Davide Gherpelli, company's spokesperson. "We can supply prototype parts in small quantities, or we can provide parts in high volume—large batches of series production. No particular sector; we think of ourselves as a 360 degree company."

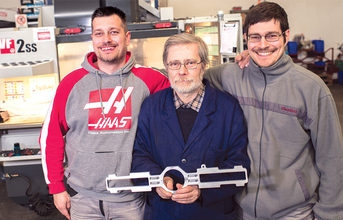

From the 1970s until 2011, Davide's father, Giorgio Gherpelli, ran G-Tech. In fact, the company began with Davide's grandfather. Davide joined the company in 2004 while his brother Mirko, ‘mago' (the magician), for his skill with the Haas CNC, joined a decade later. Now, there are five employees at G-Tech who run a very busy machine shop. "We invested in our first Haas CNC machine in 2007," remembers Davide. "An SL-10 turning centre. We then bought a Super MiniMill, an ST-10Y turning centre with live tooling, a VF-2SS high-speed mill, and a VF-1, which is our general-purpose machine. In fact, we have a Haas machine tool for almost all our machining needs. We have a very good selection!"

(Continued on next page)